Direct Fired Heater Ppt

68 heat transfer a radiation.

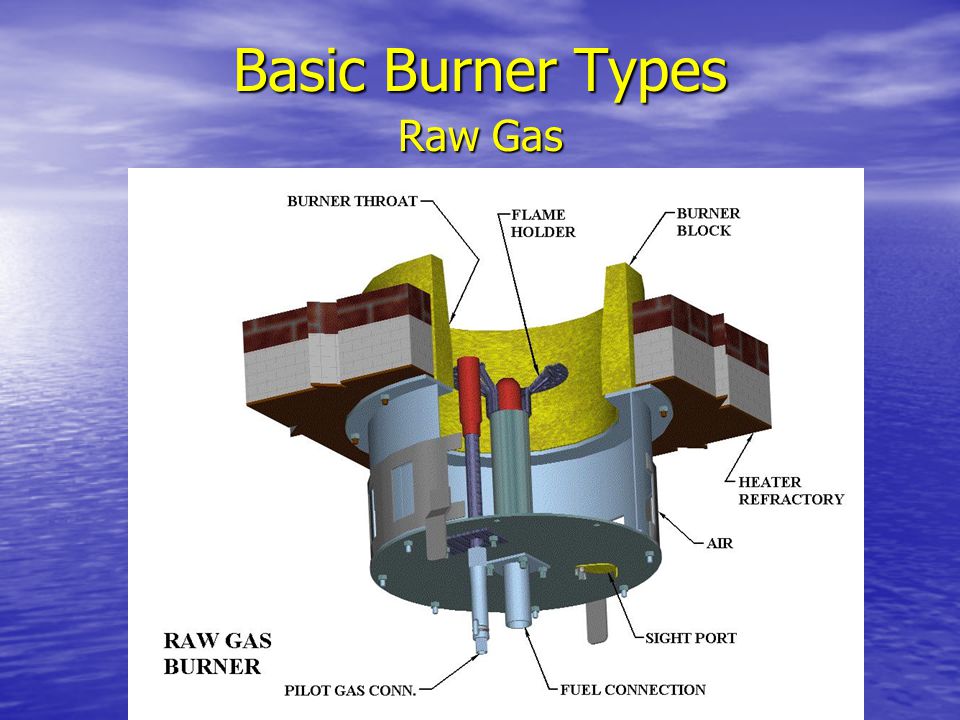

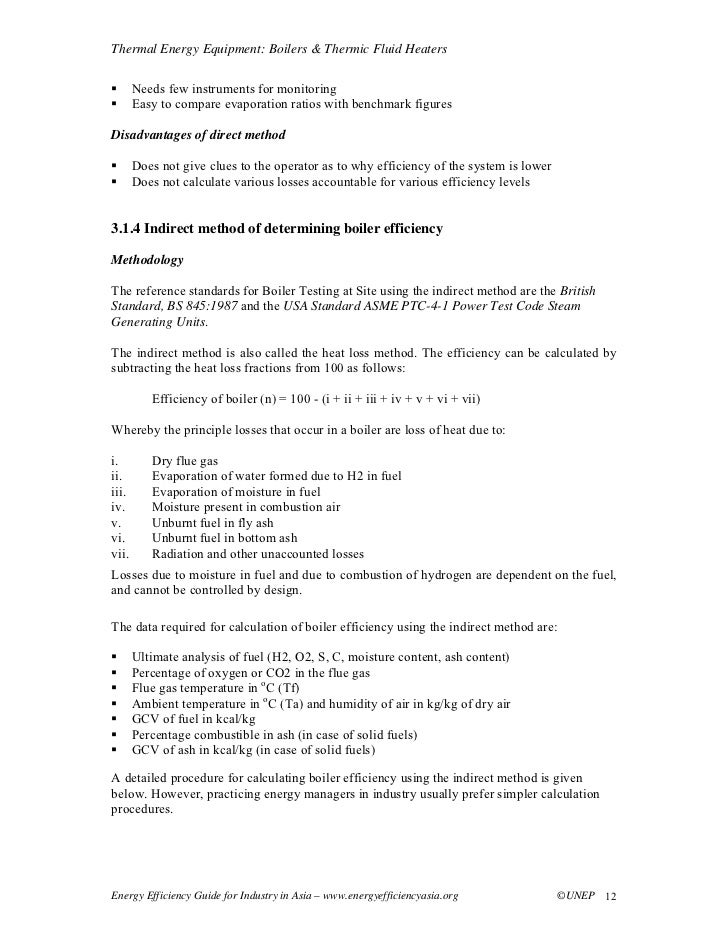

Direct fired heater ppt. Fired heaters combustion fundamentals 𝐶𝐻4 2𝑂2 𝐶𝑂2 2𝐻2 𝑂 𝐻𝑒𝑎𝑡 btu s amount of work needed to raise the temperature of one pound of water by one degree fahrenheit 1𝐵𝑇𝑈 1055 𝐽 3. Direct fired heaters are both more efficient and less expensive than indirect fired heaters. Most heaters are up fired except for special types such as ethylene crackers and reformers. Fired heaters petroskill course hector nguema ondo 2.

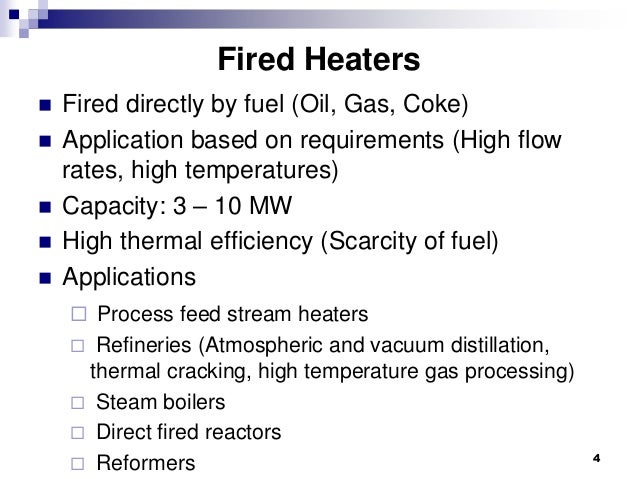

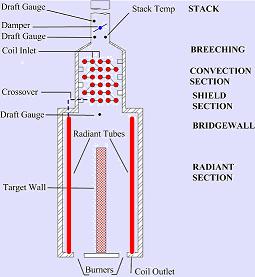

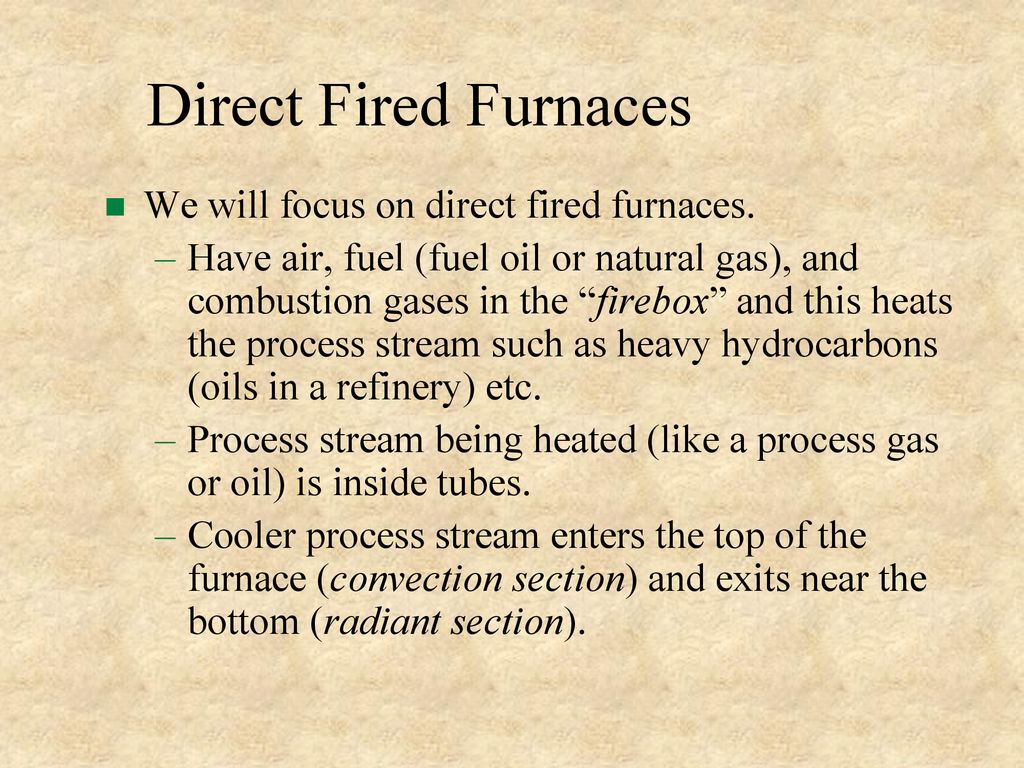

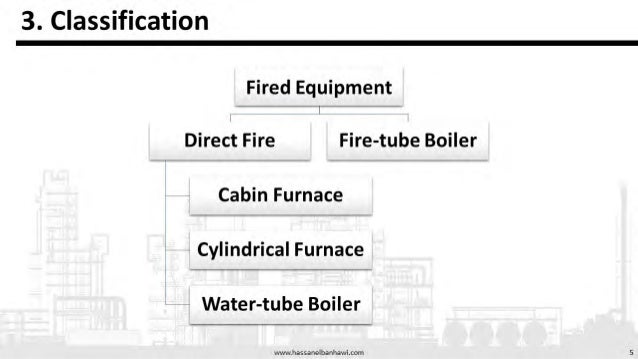

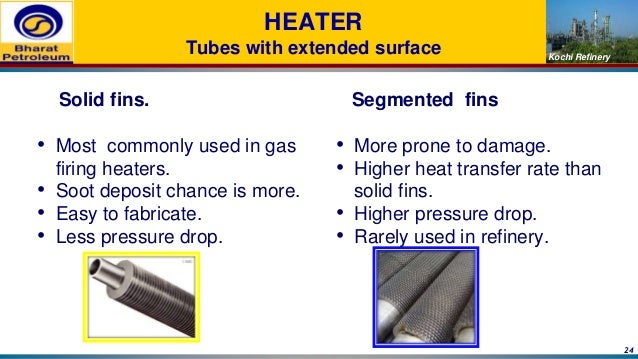

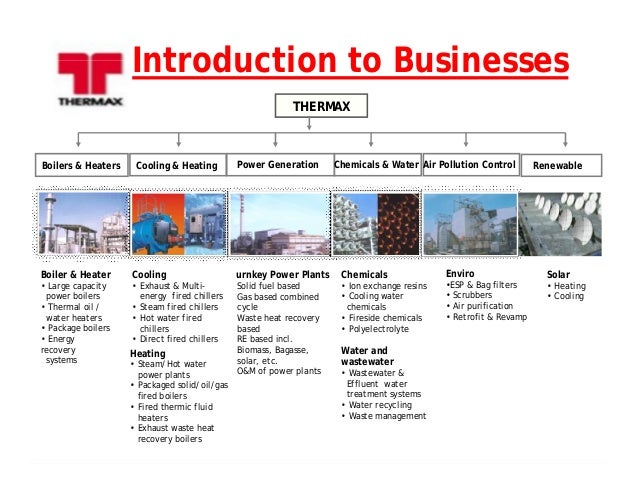

Almost every unit in a refinery needs a fired heater. Beginners guide to fired heaters 6 shield section shock section tubes that shield the remaining convection section tubes from direct radiation extended surface heat transfer surface in the form of fins or studs attached to the heat absorbing surface tube support tube sheet device used to support tubes header return bend cast or wrought fitting shaped in a 180 bend and used to. Direct fired heaters applications. Direct fired heaters can either be used in radiant or convection heat exchanges and adopt different configurations according to their applications.

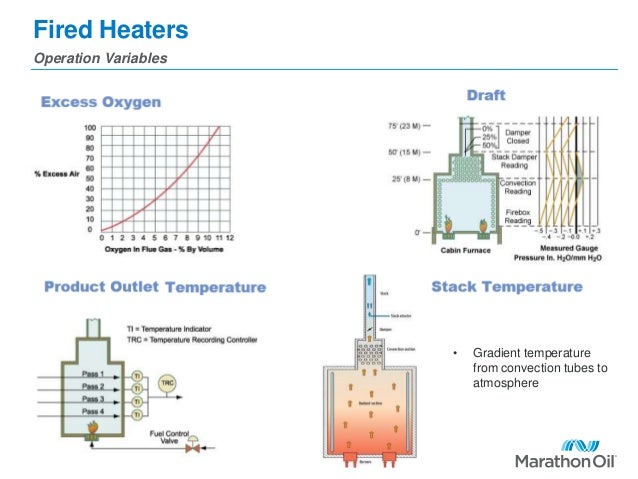

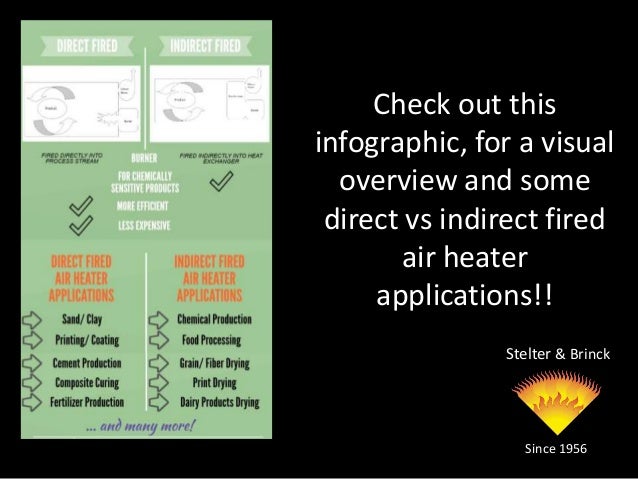

In the firebox we get heat transferred initially. Direct fired heaters can utilize radiant and or convection heat transfer sections and can be configured in many different ways depending. Direct fired heaters cannot be used in a tightly sealed structure unless windows and doors can be opened for air exchange. The types of configuration vary according to.

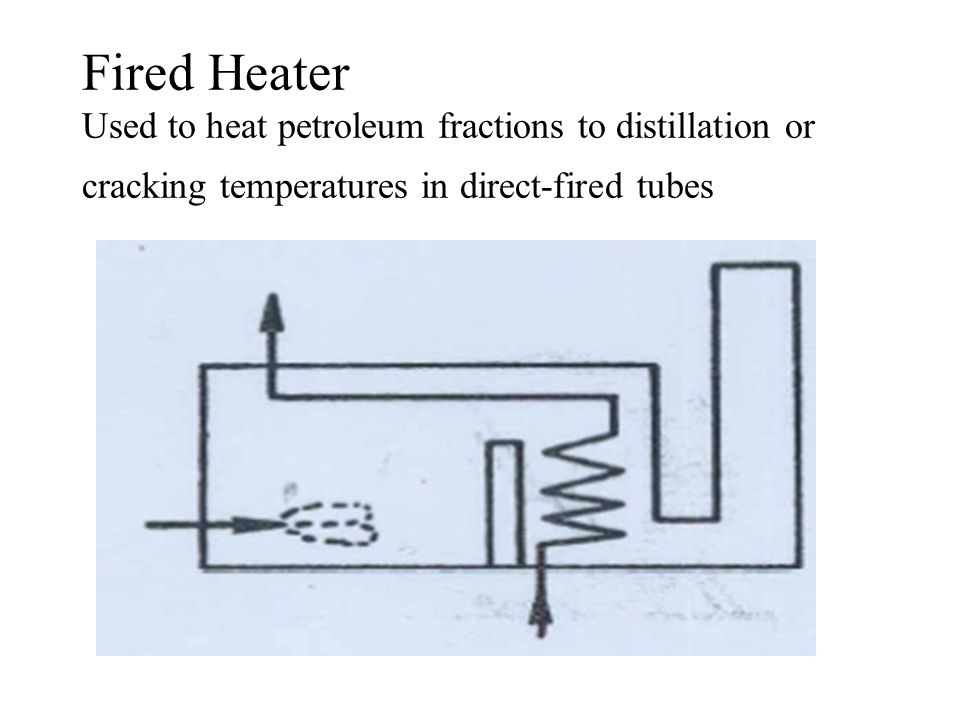

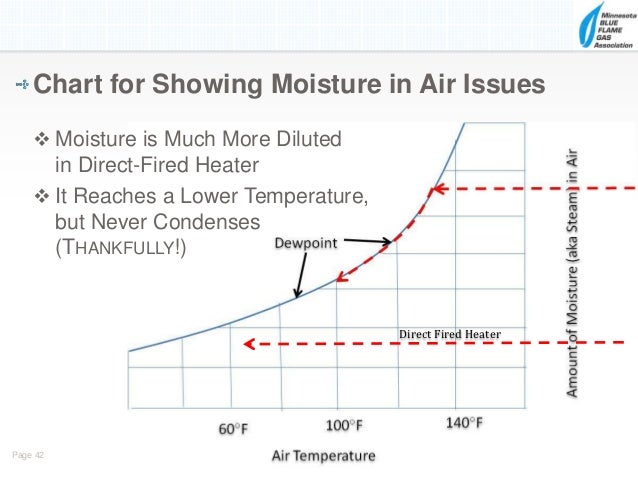

Fired heaters are one of the most important equipment in any refinery or petrochemical plant. Since direct fired heaters have an. A direct fired heater is a style of heater in which a burner provides hot gasses that transfer their heat energy to a process liquid or gas flowing directly through coils installed inside the heater vessel. Generally direct fired heaters are used on construction sites outdoor applications or warehouses.

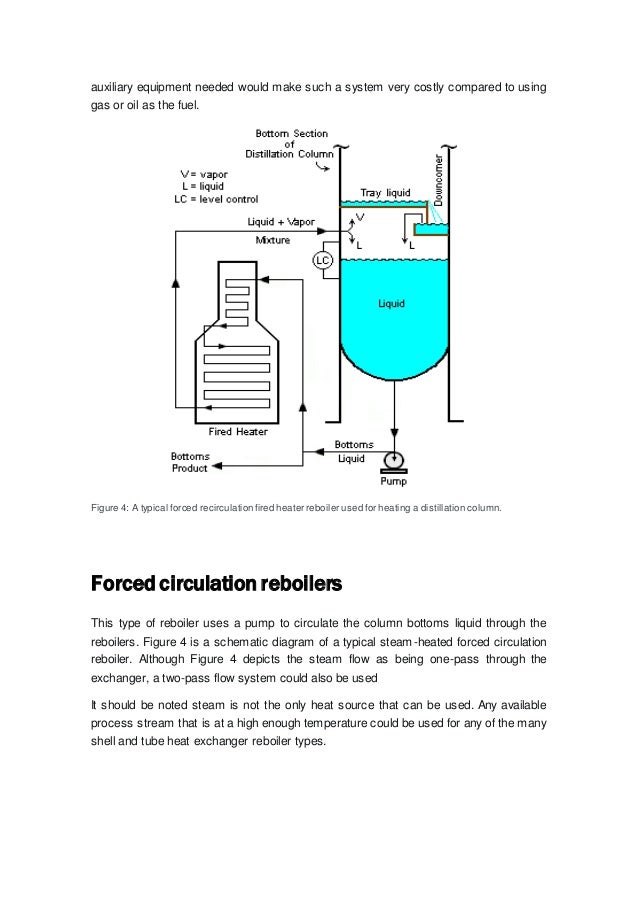

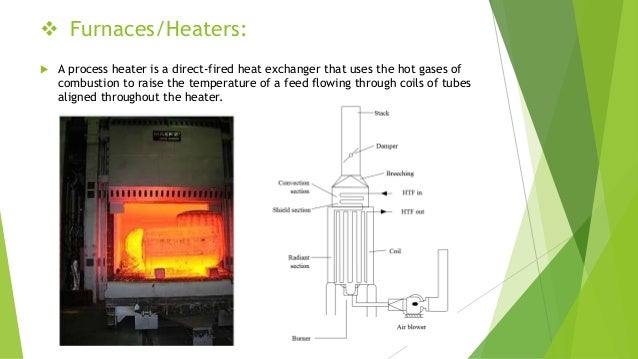

A fired heater is a direct fired heat exchanger that uses the hot gases of combustion to raise the temperature of a feed flowing through coils of tubes aligned throughout the heater. Also heaters are one of the largest consumers of fuel in the refinery and minor improvements in fuel consumption of the fired heaters can lead to quite large savings. We could consider direct fired heaters basically as custom designed equipment given that the heat is directly transmitted to the product of the process and any change in this characteristic could render the equipment ineffective for the new conditions of the process or even destroy the product or equipment due to unsuitability. Having a thorough understanding of all of the differences between these two heater types will ensure you choose the optimal solution for each project.

Depending on the use these are also called furnaces or process heaters. Introduction of fired heaters 1. However there are some cases where an indirect fired heater is the better choice. Some heaters simply deliver the feed at a.