Design A Sheet Metal Part From The Flattened State

In the browser double click the folded model node to return to the folded model state or.

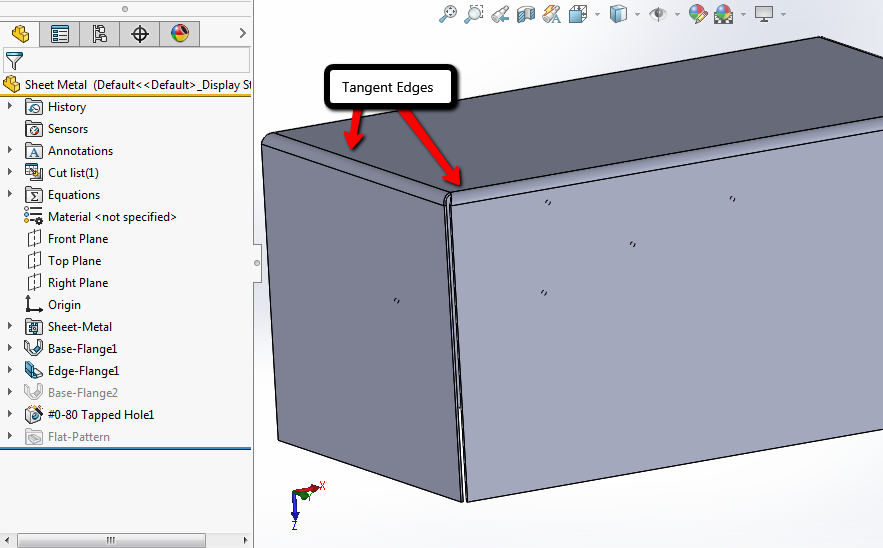

Design a sheet metal part from the flattened state. In the propertymanager under bend parameters. It is designed for materials like cloth or leather but can be used for metal if there will be forming involved. Create a part by sketching the part profile then extruding a thin feature part. Open a new part.

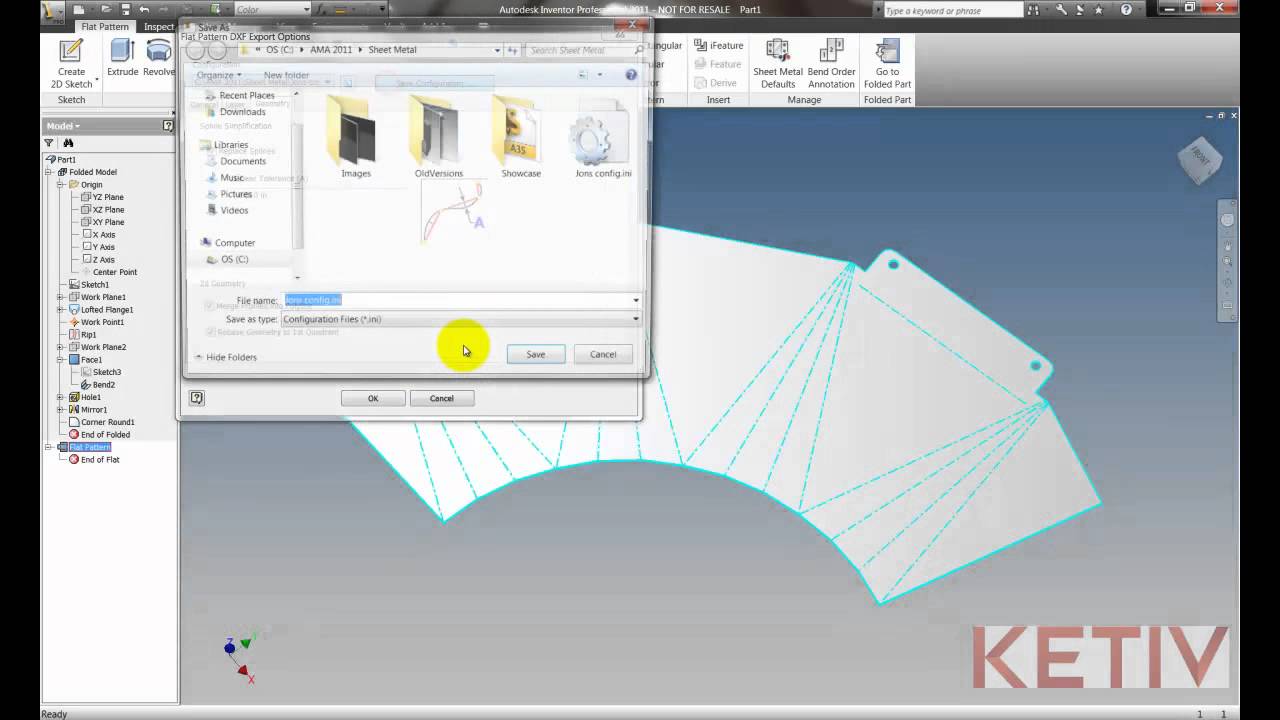

With a single body sheet metal part open on the ribbon click sheet metal tab flat pattern panel click create flat pattern. Upholstery clothing even carbon fiber layups can be calculated using this feature. The flat pattern is created and displays. Choose the flat representation of your sheet metal part and click edit.

In the view manager define a combined state of orientation and flat rep by clicking new and typing in a name for the flat view. Design a sheet metal part to meet unique sheet metal design challenges like manufacturability solid edge streamlines the entire sheet metal product development process from cad design through flat pattern and drawing development. Develop sheet metal models with fewer steps. You may want to design a sheet metal part from the flattened state.

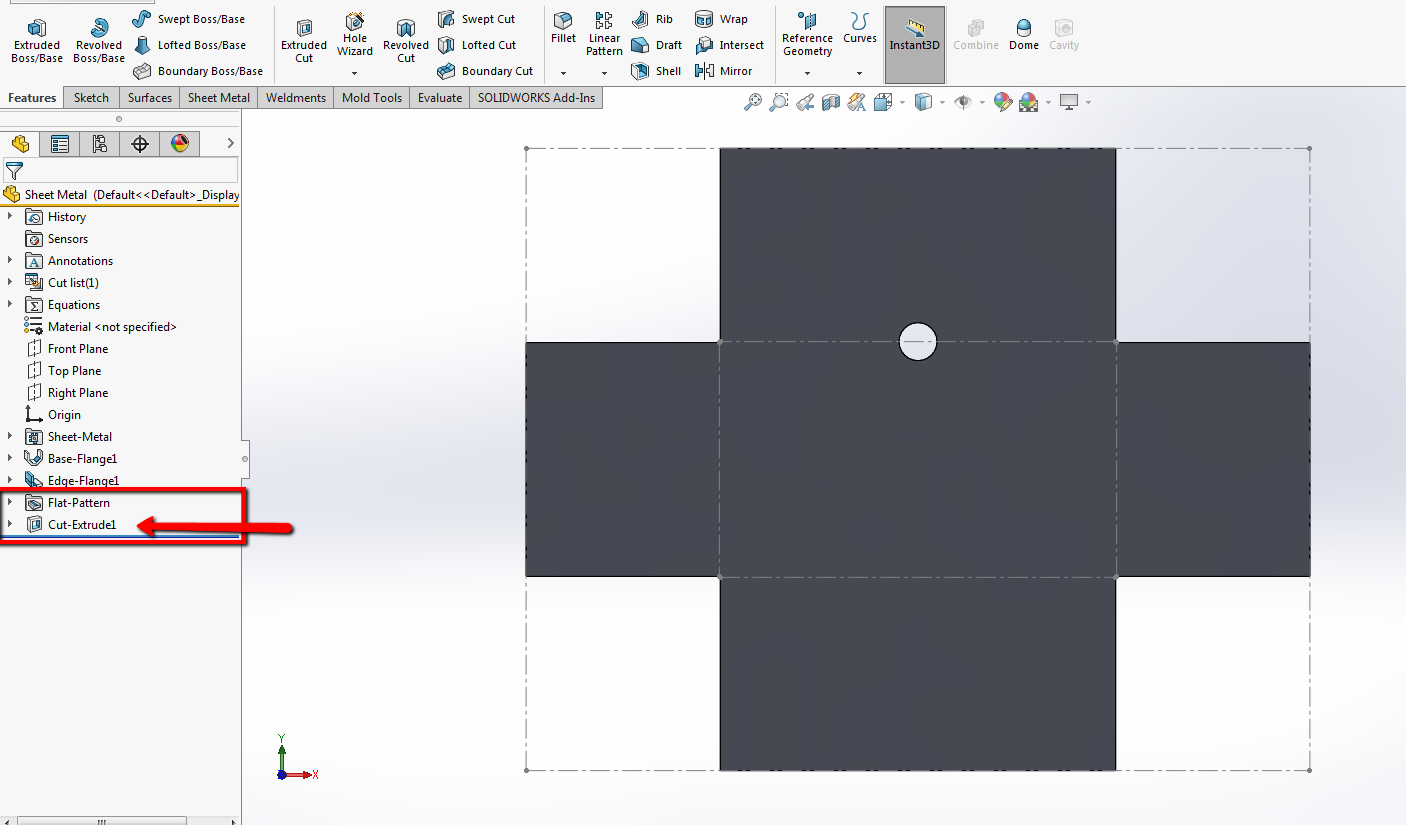

A flat pattern node is created in the browser. In this case you create a sheet metal part then insert bend lines on which to fold the part. Flatten surface is only available in solidworks premium and is really the last chance for a part to be flattened from a 3d shape in automated way. The name of the face is displayed in the fixed face or edge box.

Choose redefine in the drop down menu. To create a sheet metal part from the flattened state. Click insert bends or click insert sheet metal bends. In the options window change the simplified rep to flat and click ok.