Depletion Of Resources Used To Make Solar Panels

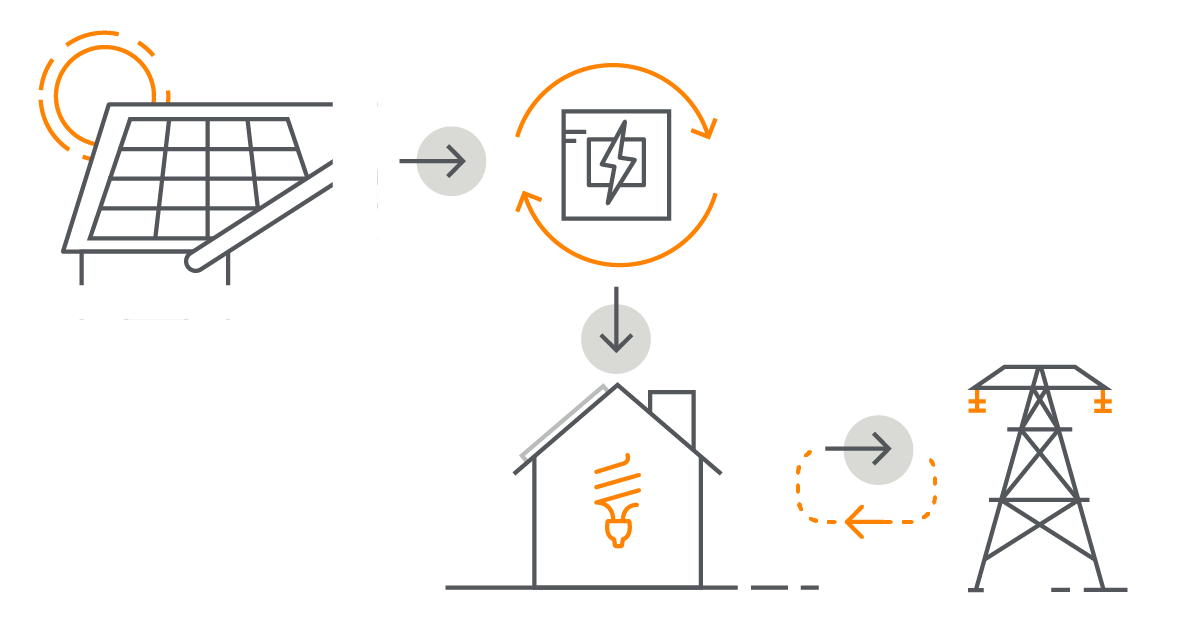

With assumed life expectancies of 30 years and taking into account the fossil fuel based energy used in manufacture 87 to 97 of the energy that pv systems generate won t be plagued by pollution greenhouse gases and depletion of resources.

Depletion of resources used to make solar panels. Solar panels will never generate enough power to offset the energy that was used to manufacture them in the first place. Sawing silicon into discs for use creates silicon dust called kerf with up to 50 waste. So a solar panel will make many times more energy than it takes to make it. Then it makes energy with no energy cost at all for the rest of its life.

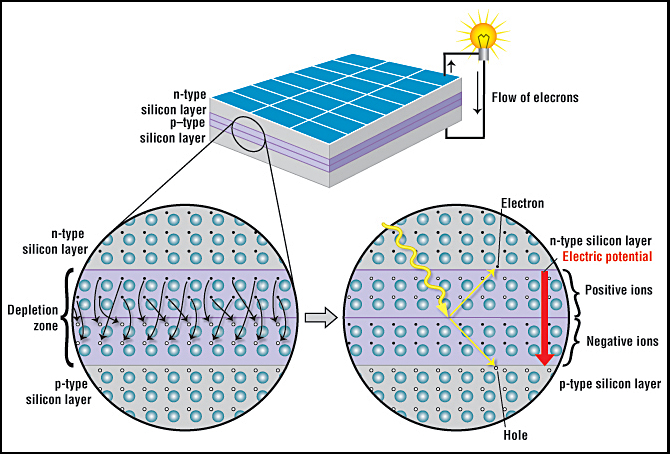

1 like recently a customer of ours raised the concern that he had heard. When assesing solar panels as a key energy resource it is important to weigh up any concerns. From there the grade must be further purified into polysilicon the solar grade purity of which is 99 999 percent. Some potential issues include.

The silicon in solar panels is manufactured through a reduction process in which the silica is heated with a carbon material and the oxygen is removed leaving behind purer metallurgical grade silicon. Some of the materials used to make solar panels can be hazardous to both our health and the environment. Even ten years ago this study said it takes about 2 years of energy generation to pay back the energy used to make the solar panel. The following table details some of the hazardous materials that can be found on a solar panel.

Based on models and real data the idea that pv cannot pay back its energy investment is simply a myth.

/Solarpanels-3156a12e053e49c88e4d7f53254fb8a8.jpg)