Depalletizing Sheet Metal

The speed of the belt conveyor is generally controlled by frequency conversion to ensure synchronization with the subsequent washing machine and oilier.

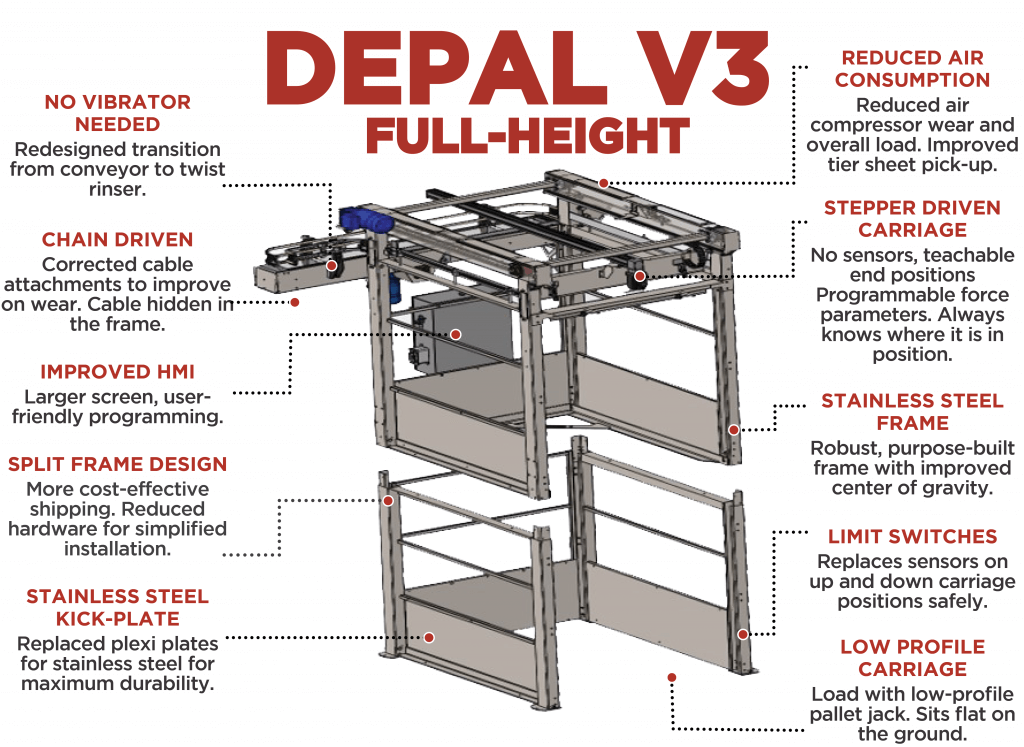

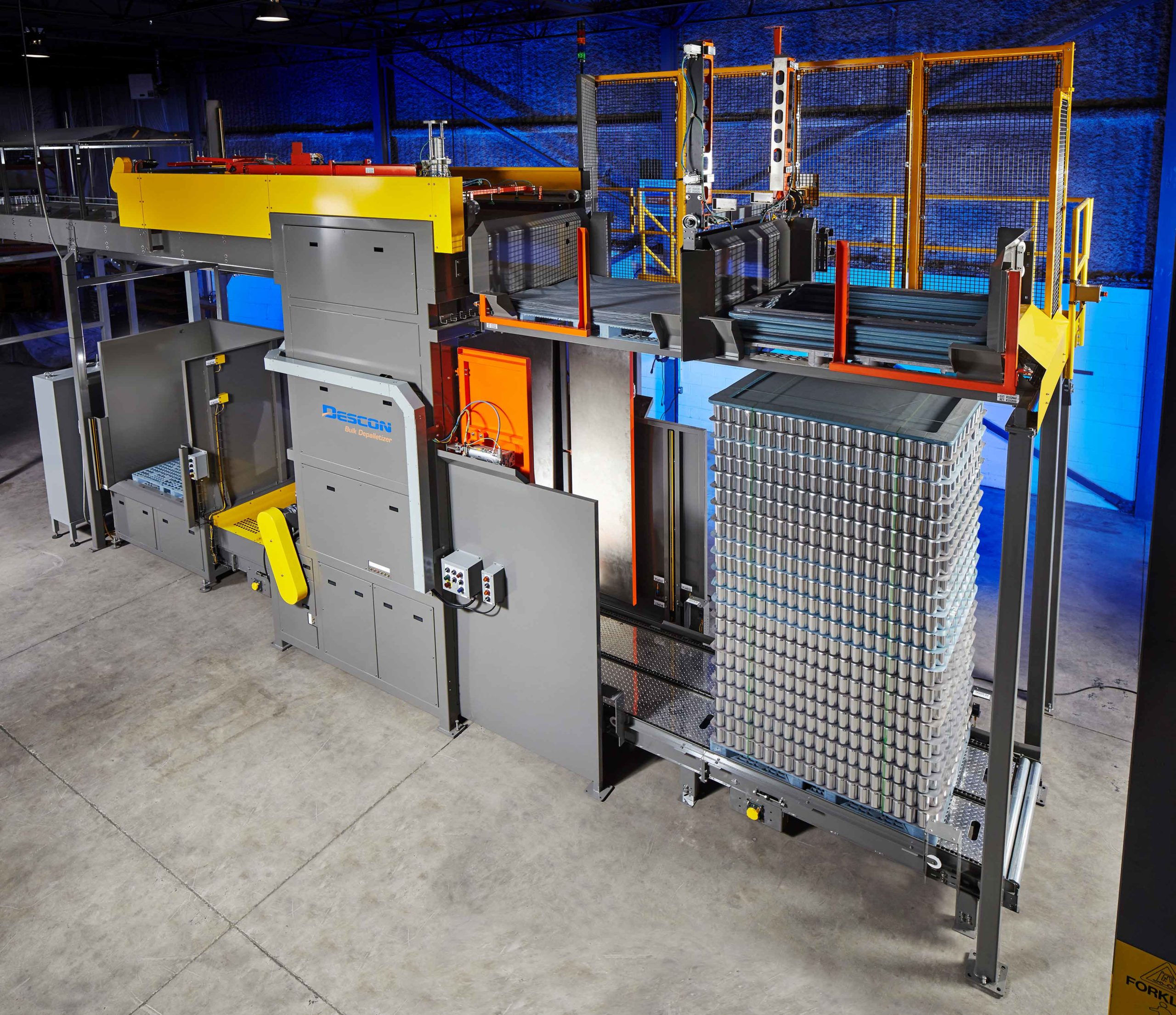

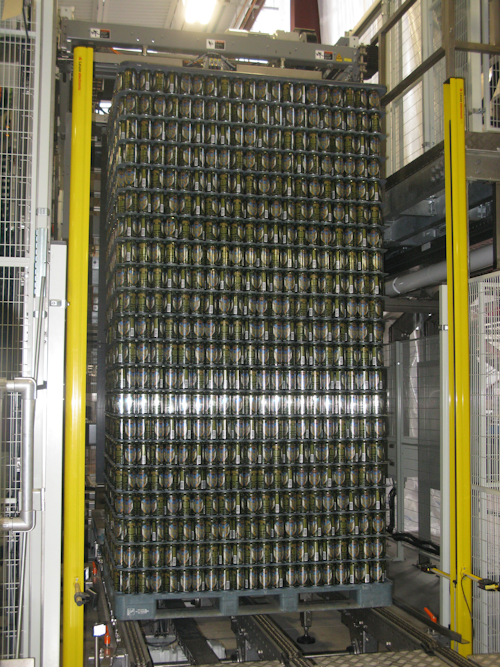

Depalletizing sheet metal. System available in three versions. Using a 3d area sensor allows depalletizing both homogeneous and heterogeneous unit loads. Start 1000th and finish 1st. The can i bus depalletizer is fully automated once the pallet is inserted and the straps and tier frame are removed.

Palletizing of scrap metal bales poses many challenges to plant operations due to the variability in bale dimensions the weight of bales and the inherent safety issues that come with handling bales. It is designed with space and cost in mind and is capable of depalletizing multiple sized packages of aluminum and metal containers. Semi or fully automatic depalletizing. Gross package weight can be adjusted on customer requests vreden germany depalletizing of heavy metal sheet packages is tortuous and binds resources.

California sheet metal is the most capable firm in southern california for complex sheet metal and paneling projects that demand the utmost quality. Mountain of hell the biggest mtb mass start on earth. Hillman 12 in x 24 in cold rolled steel expanded sheet metal. Owlaps recommended for you.

Item 168753 model 11786. Nick novak vice president lusardi construction i have worked with california sheet metal for nearly 20 years on projects large and small simple and complex. The ska fabricating can depalletizer is the original small footprint semi automated depalletizer. Layer depalletizer rasar d200 faster d200.

Robotic scrap metal palletizers provide increased safety while meeting or exceeding your system requirements. Installation of the provided punches for the böckelt depalletiser is a breeze they are simply housed. Sheet metal depalletizer easy installation of the böckelt depalletiser the böckelt depalletiser can be stowed in the böckelt tower just like any cassette. Easily perform secondary functions video courtesy of kaufman engineered systems whether it s layer forming slip sheet or pallet handling the flexibility of robotics allows for the seamless execution of secondary functions.

Gida2 put blocks between the pallet and bottom sheet of steel for forks to enter. The extensible belt conveyor is used to transfer a single sheet after completing destacking and it can provide the required moving speed for sheet metal through the washing machine.